Redwood Materials

@redwoodmat

Building a circular supply chain to power a sustainable world.

ID: 888493805158019073

http://redwoodmaterials.com 21-07-2017 20:20:05

259 Tweet

25,25K Takipçi

98 Takip Edilen

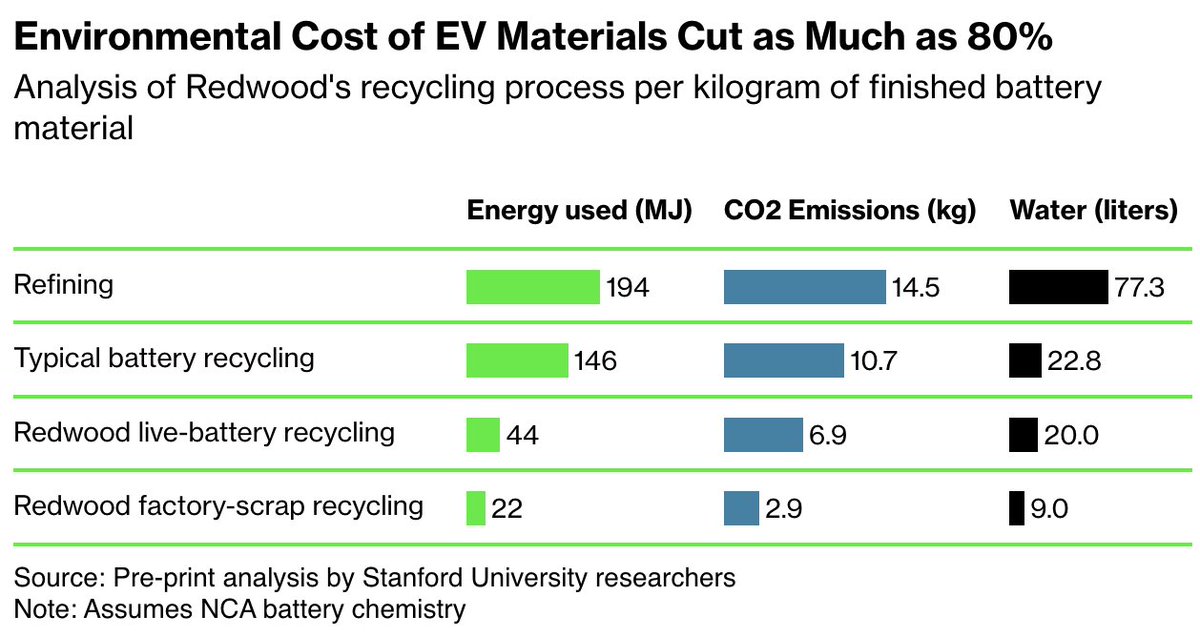

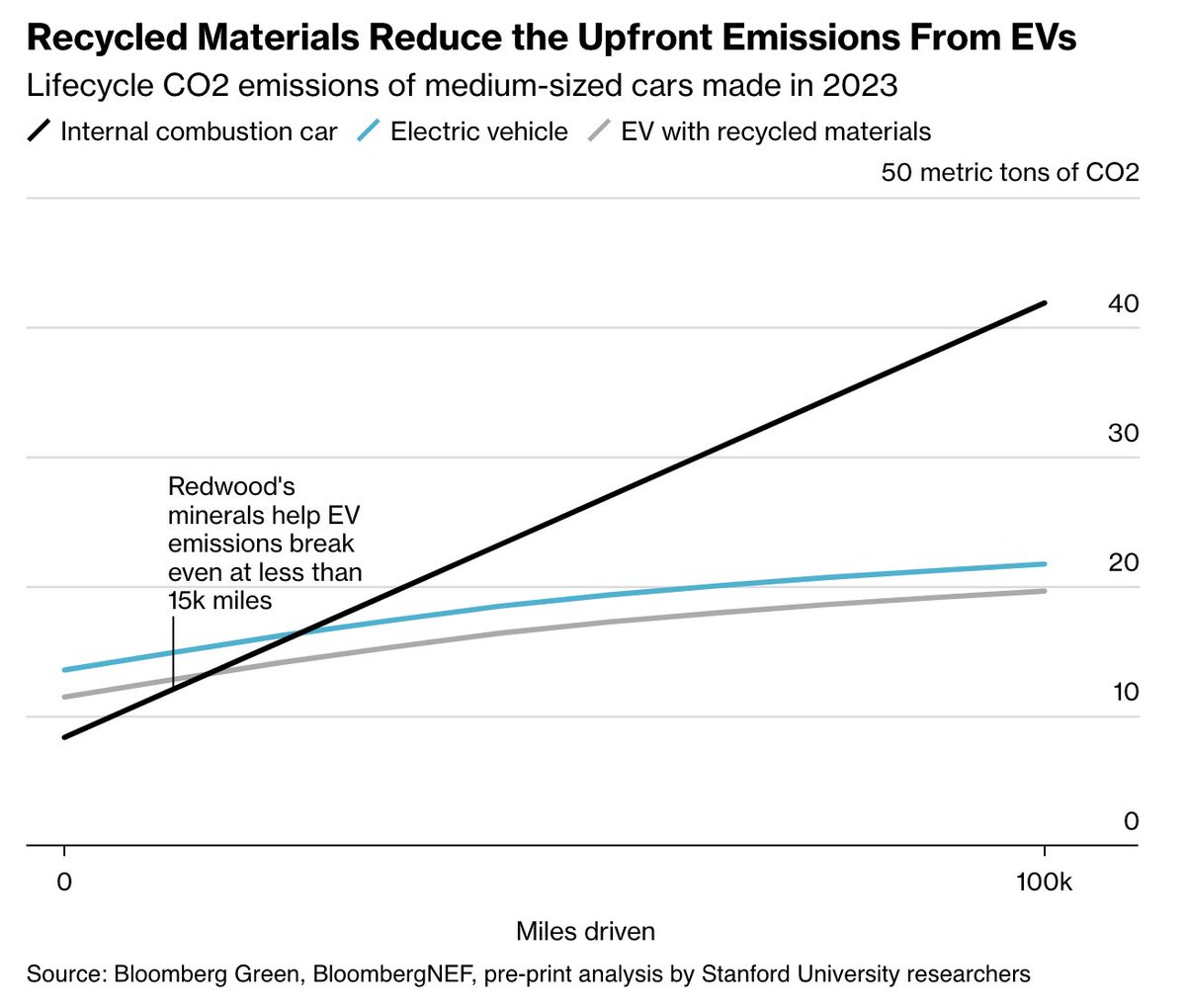

We’re building America’s battery supply chain: ✅ First commercial-scale nickel "mine" and only lithium supply to come online in the US in decades. ✅ Stanford University shows we cut CO2 by 40% compared to other recyclers and, at a 15-20 GWh processing scale already! ✅ Environmental

Every day is Earth Day at Redwood! Stanford University's recent study confirms we're driving scalable change in recycling and battery materials production.

Don't let anyone tell you that EV batteries just end up as toxic landfill waste. They're simply too valuable to toss out. Though still in its infancy, EV recycling is already widespread, profitable and capable of recovering more than 95% of key minerals. bloomberg.com/news/articles/…

On Earth Day, our Rotary International partners collected thousands of pounds of batteries from their communities in just a few hours. They shared their experience working with us create a more sustainable future. Inspired to host or attend an event? Visit redwoodmaterials.com/recycle-with-us

We’re partnering with Ultium Cells (the General Motors and LG Energy Solution joint venture) to recycle 100% of the production scrap from their Ohio and Tennessee battery plants. Together, we’re building America's battery supply chain. redwoodmaterials.com/news/redwood-u…

Compared to traditional methods of processing mined ore, Redwood uses 80% less energy, generates 70% fewer CO2 emissions, and requires 80% less water, setting new standards in resource efficiency. More on our Tahoe Campus and Stanford University University's findings:

"By providing a domestic source for cathode materials, Redwood not only provides a conflict-free source of these materials, but further establishes itself as a key part of the developing EV battery ecosystem in the United States." -motortrend Tim Stevens motortrend.com/news/ev-batter…